Congratulations on China's conquering of multi-axis CNC machine tools and solving the problem of 400-ton propellers

Release time:

2020-07-28

?

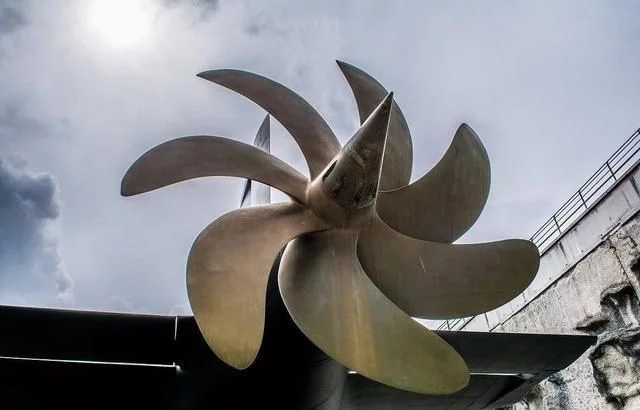

As one of the powerful maritime weapons, aircraft carrier is welcomed by all countries in the world. Therefore, all countries are scrambling to build aircraft carrier. Although China started late in aircraft carrier technology, it has also made remarkable achievements in its development. With the launch of China's domestic aircraft carrier, the world is paying more and more attention to China. Recently, my country once again came good news: China has conquered multi-axis CNC machine tools and solved the problem of 400 tons of propellers.

?

?

Today, the aircraft carrier has become a significant symbol of a country's comprehensive national defense strength, but its research and development process is extremely difficult. As we all know, ships will face greater resistance when traveling at sea than on land, and the size of aircraft carriers is huge, which requires strong power support, so the propeller must be strong enough.

?

?

Because the propeller is immersed in seawater for a long time, it must have a strong ability to resist seawater corrosion, but also have sufficient strength, and for safety reasons, the noise of the propeller cannot be too large. One after another stringent requirements restrict the development of propellers to a certain extent, and R & D teams in various countries are also racking their brains for this.

?

?

Although the shape of the propeller looks relatively simple, the design principles contained in it are extremely rich. Materials science, engineering, fluid mechanics, etc. are fully reflected in the propeller design. Among them, the propeller manufacturing process used on the aircraft carrier is the most complicated. The reason why the United States can stand at the top of the manufacturing industry is that it has mastered a large number of cutting-edge technologies. For example, the propeller of the Nimitz aircraft carrier in the United States is made of bronze alloy, which is as high as 6.4 meters. A single propeller weighs 150 tons. From the curvature of the propeller to the smoothness of the propeller, the overall performance is relatively excellent.

?

?

However, since the propeller is fully completed manually, it takes at least half a month to complete one. But despite this, there are few countries in the world that have the ability to build aircraft carrier propellers, but it is proud that China is one of the few.

?

?

Now, after more than 1000 days and nights of tackling key problems, the new seven-axis five-linkage CNC machine tool developed by our country has laid a solid foundation for the manufacture of domestic aircraft carrier propellers. It is understood that China W?rtsil? Propeller Company has fully mastered the manufacturing technology of large propellers. The maximum diameter that the company's machine can process is as high as 12.5 meters. Moreover, it uses intelligent technology for processing. As long as the technicians input specific programs, the machine tool will operate according to the preset settings. It only takes three days to produce a propeller. This efficiency is 12 days faster than that of manual manufacturing in the United States, the working time is greatly saved, and the performance and accuracy of the propeller can be well guaranteed.

?

?

In addition to the progress of processing technology and methods, China has been steadily advancing in the production of propeller materials. In the 1970 s, we used brass zinc tin alloy. Now, we have kept up with the trend of the times and started to use nickel aluminum bronze alloy. Now that the 400-ton propeller is on the market, many countries have speculated that my country's third aircraft carrier is likely to be a 100000-ton aircraft carrier, and may even catch up with the US aircraft carrier. The progress of propeller technology will promote the development of aircraft carrier technology, which is also the best proof of the continuous improvement of China's manufacturing capacity. The progress of processing technology and the continuous research and development of processing materials all show the progress of propeller technology in our country. It is no exaggeration to say that our country now has the ability to independently produce various types of propellers.

?

?

Although our country has made great achievements in the field of propellers, we still can't slack off, especially in the production of key precision instruments. After all, for high-end precision instruments, it is a thousand miles away!

Related News